Safety is critical in the materials handling industry. Industry statistics estimate that approximately one out of every 10 forklifts is involved in an accident in the United States each year. However, OSHA also estimates that approximately 70 percent of these accidents could be avoided through better adherence to standardized training and safety procedures. That significant reduction in accidents can, in turn, help decrease occupational injuries and associated costs. But how do you know if your operation is doing enough to support lift truck operating best practices?

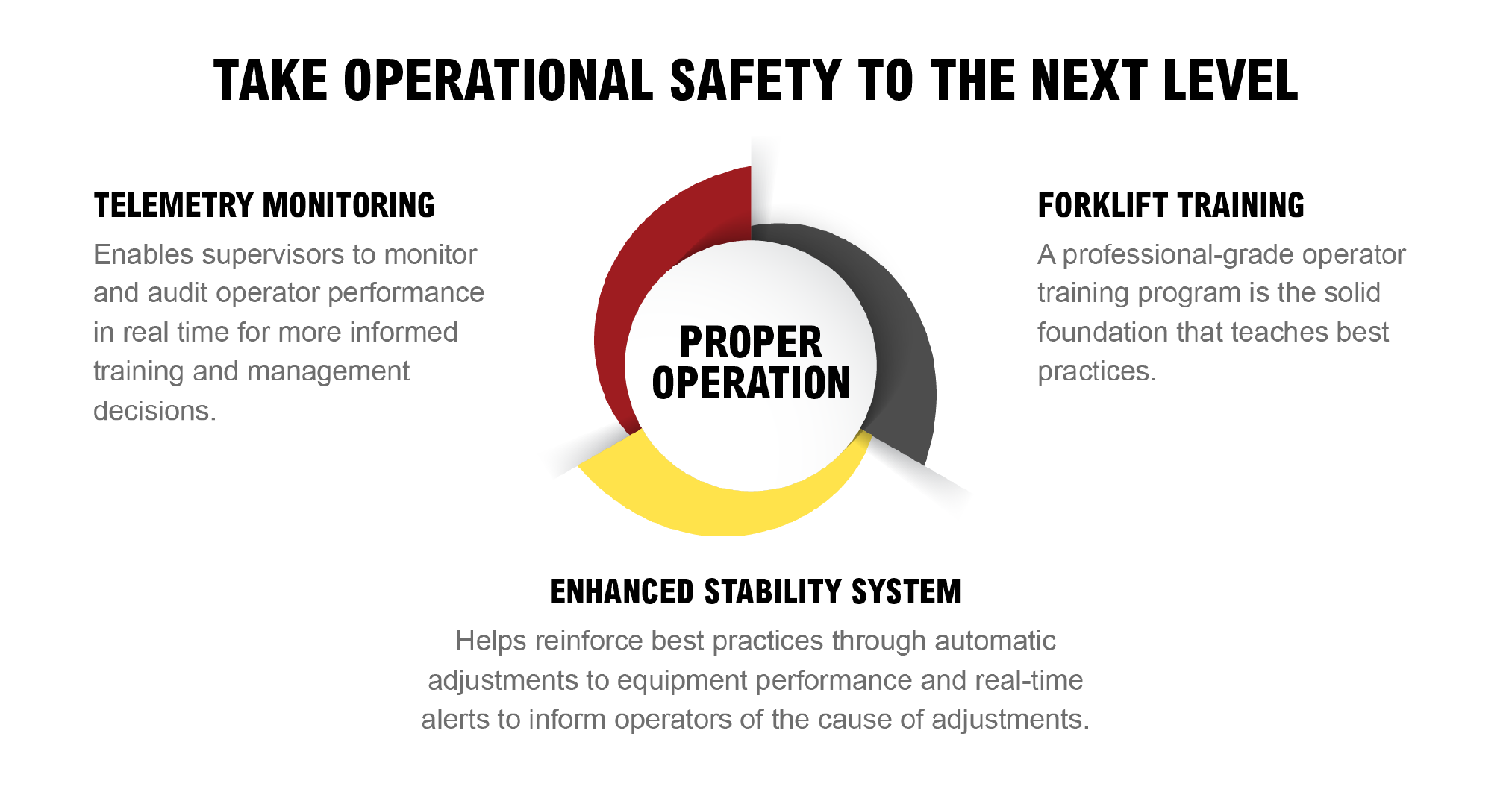

The truth is, there’s no single, silver bullet – forklift safety requires a comprehensive, multi-faceted approach, including training, real-time support and monitoring, and reactive evaluation after-the-fact.

In addition, you need to partner with a material handling supplier that can help support your lift truck operating best practices. Here are three layers of forklift safety practices that LiftOne can help support so you can build a comprehensive forklift safety strategy for your operations.

- Forklift training: build a strong foundation.

- Telemetry: monitor operator performance in real time with a telemetry tool like Hyster Tracker and Yale Vision

- Enhanced stability system: help reinforce best practices with forklift technologies like operator assist systems (OAS) with Hyster Reaction and Yale Reliant, and dynamic stability system.

Contact LiftOne for More Information

LiftOne is your source for the warehouse equipment and aftermarket solutions you need to get the job done safely and efficiently. Contact us today for more information on how we can help you operate a safe and effective warehouse.