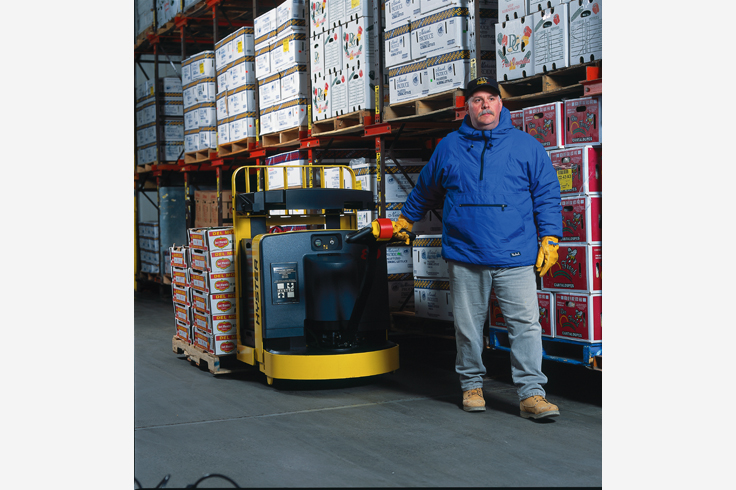

W60-80Z Hyster

- Decreased downtime

- Enhanced productivity

- Built to handle harsh environments

- Easy serviceability

- Models: W60-80Z

- Capacity: 6000-8000lbs

- Load Weight: 8000lbs

- Max Lift Height: 9.3

- Environment: Indoor

- Power: Electric

- Primary Task: Ground Level Transport Only

- Auto Manufacturing

- Beverage

- Chemicals & Plastics

- Food

- Logistics

The energy efficient, Separately Excited Motor (SEM) transistor controlled 24-volt system results in a walkie pallet jack with fewer parts to help minimize downtime and service needs. The SEM transistor controller’s current sensing feature provides you end-of-lift-stroke sensing with automatic motor shut down, lengthening motor life. In addition, the SEM systems solid-state controller appreciably improves torque and loaded travel speed throughout the truck’s range of operation, increasing productivity.

When was the last time you felt great about a capital purchase? You will, the first time you operate our walkie electric pallet jacks. They’re designed to fit into those tight spaces. You know – the ones where you place everything you didn’t need right then, but you need it now.

Infused with the integrity of over 70 years of materials handling manufacturing expertise, this truck has what it takes to move your operations productivity to the next level.

If you operate in a harsh environment, you’ll appreciate our optional cooler/freezer, SubZero or extreme corrosion/wash down packages.

The Extreme Corrosion/Wash Down Package includes a completely galvanized frame, lift linkage, battery well and fork weldment. The galvanized frame pallet truck is designed for use in highly corrosive environments like food processing, pickling, tannery, chemical, salt and brine industries (W65Z, W80Z models).

Reduced wiring complexity and fewer service parts contribute to less required maintenance and longer truck life.