Keeping Your Team & Fleet Safe to Maximize Uptime & Productivity

Prevent accidents before they happen.

At LiftOne, we’re committed to keeping you and your team safe. We pride ourselves on providing forklifts designed and built for optimal operator and pedestrian safety, however we know accidents can still happen. According to OSHA:

96,785

forklift injuries occur each year

1 in 10

forklifts will be in an accident

70%

of forklift accidents are preventable

1 in 6

U.S. workplace fatalities are forklift-related

Enhance Your Forklift's Safety

PLANNED MAINTENANCE

Having routine maintenance on your fleet reduces the chance of unexpected repairs and breakdowns. This will improve your equipment’s performance and help ensure it is safe and reliable, before your operators start work.

- Maintenance plan options built around your utilization and operating environment

- 65 multi-point inspection, including factory-recommended maintenance, documented for your future reference

- Safety checks and recommendations for improvements performed by trained technicians

TELEMETRY

Promote safety and monitor your operator’s behavior with LiftOne’s turnkey wireless fleet tracking tool. Providing a detailed look at your fleet’s daily operations so you can pinpoint areas of inefficiency or misuse.

- Receive alerts on forklift impact with recorded data on speed, direction and force of impact

- Prevent access to the unit by an untrained operator

- Require OSHA cloud-based safety checklist prior to operating

- Monitor equipment diagnostics to help provide maximum uptime

SAFETY ADD-ONS

Adding safety accessories to your forklifts and other equipment can help prevent accidents, asset damage and downtime. LiftOne’s extensive safety solutions include:

- Forklift alarms and advanced warning systems

- Seatbelts and fall protection

- Red, blue and strobe lights

- Speed limiters

- Blindspot cameras

- and more

Protect Your Operators

TRAINING & CERTIFICATION

Never let anyone who is not certified operate a forklift. Offer your employees the same level of safety training our own people live by, including:

- Comprehensive operator training customized for your business and equipment

- OSHA-compliant “Train the Trainer” classes allowing you to offer on-site training

- Annual refresher and new hire certification courses available

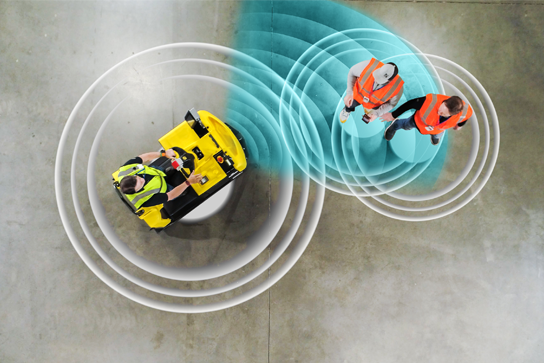

DETECTION SYSTEMS

Keep your operators informed of pedestrians and obstacles in close proximity, helping improve awareness, safety and preventing accidents before they happen.

- Pedestrian alert systems inform operators and pedestrians through audible and visual warnings

- Collision avoidance systems reduce accidents in blind corner intersections through warning systems

- Operator assist technology keeps operators in control but more aware of their environment including travel speed, load stability, object and proximity detection

Minimize Product & Facility Damage

WAREHOUSE & DOCK SAFETY

Warehouses hold unique hazards and proper safety products must be in place to prevent accidents and minimize product damage. From the essentials to advanced safety equipment, LiftOne has you covered:

- Safety barriers and guard rails

- Column protectors

- 5S floor marking tape

- Blind spot and high-traffic intersection mirrors

STORAGE RACK MAINTENANCE

Constant wear and tear of your warehouse racks can easily be overlooked. Identifying damage and scheduling maintenance can reduce avoidable accidents to your product, equipment and most importantly—team.

- Proactively conduct regular racking inspections

- Perform maintenance to prevent accidents and extend life of infrastructure

- Schedule tour of your facility with LiftOne’s trained team for safety enhancements and recommendations

Related Blog Posts

Want more safety tips? Read our blog to learn more from our team of safety experts, with preventative safety tips to keep your team safe.

Prioritizing Safety Every Day: Why National Forklift Safety Day Matters

At LiftOne, we believe safety isn’t just a checklist item—it’s part of who we are. That’s why we’re proud to recognize National Forklift…

Read MoreMaking sense of the “Safety Triangle” – Three layers of forklift safety best practices

Safety is critical in the materials handling industry. Industry statistics estimate that approximately one out of every 10 forklifts is involved in an…

Read MoreSafe Storage and Stacking in the Warehouse

While many of the safety concerns presented in a warehouse environment involve the use of forklifts or other heavy machinery, there are also…

Read MoreHave Questions on Safety Solutions?

Let us find the best safety solutions for your facility.